Complete guide to road cycling tyres

Everything you need to know about road tyres: how they work, the different types and sizes, the jargon and more

James Howell-Jones

Junior Writer

With so many different types, technologies and sizes available, bike tyres can seem pretty confusing. You hear people talking about rolling resistance, rubber compound and pressure, but what does it all mean?

This is our deep dive into the world of bike tyres. We’re going to explain everything you need to know about road bike tyres, whether you’re in the market for a new set, or just looking to get a better understanding of this essential part of bike tech.

Read more: Thin vs wide: which tyre is right for you?

Role of tyres

© GCN

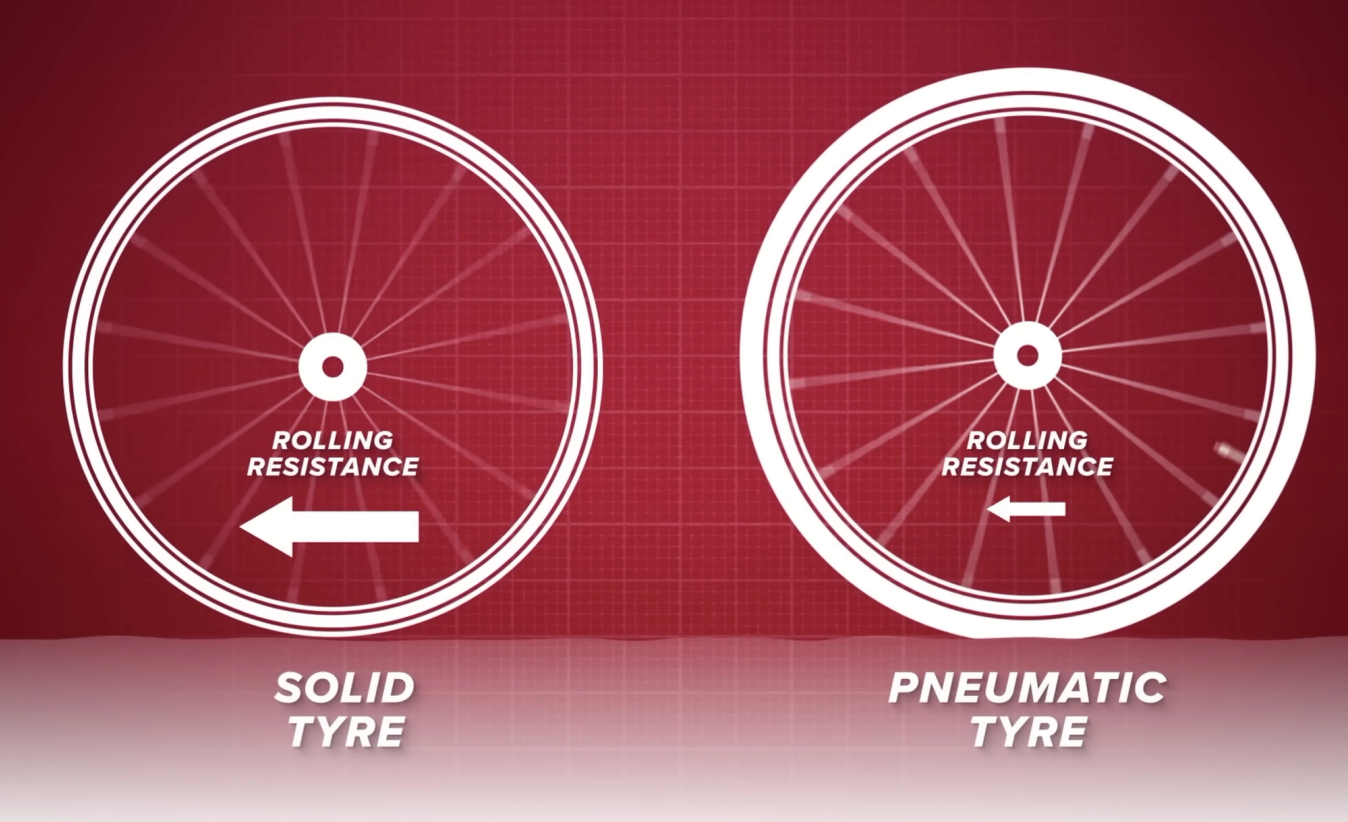

Pneumatic tyres have lower rolling resistance than solid tyres

At the most basic level, tyres provide grip, which is essential for balancing, turning, accelerating and braking. When discussing tyre grip, we're simply referring to the friction between the tyre surface and the surface that you're cycling on.

Compared to the solid tyres that preceded them, pneumatic tyres have a very low rolling resistance. The cushion of air within a tyre smoothes out the bumps in the road, which not only improves comfort, but also helps a wheel maintain its rotational speed. This is really important because, after aerodynamic drag, rolling resistance is the largest force acting to slow us down when we’re riding on a flat surface.

These days, we want so much more from our tyres than a bit of cushion and grip. We want them to be lightweight, resistant to punctures and fast rolling. For gravel or off-road uses, we might want them to have extra traction or volume. And, of course, we often want all of that for the lowest cost possible.

With so many different factors to consider, you can see why we have so many different options to choose from. And that's before even considering size, width, compound, and everything else there is to think about when choosing new tyres.

Anatomy of a tyre

Tyres have three main components: the casing, the tread and the bead.

Casing

The casing is made up from thin nylon or cotton fibres woven together and encased in a thin rubber layer. Different tyre casings have different thread counts, which determines the quality of the tyre. More on that shortly.

Tread

Then there’s the tread, which covers the central part of the tyre, and makes contact with the road. The amount of grip this outer layer offers is determined by the tread pattern and the rubber compound, which we’ll get into later.

Bead

On each of the sides, we have the tyre bead, which is the part that sits on the wheel rim. Older or lower end tyres tend to have a non-folding wire bead, but most modern tyres will have a flexible folding bead, which are usually lighter.

How the tyres are held on the rim

The way your tyre is held on the rim is called the fitment type, and there are three different options out there.

Clincher tyres

© GCN

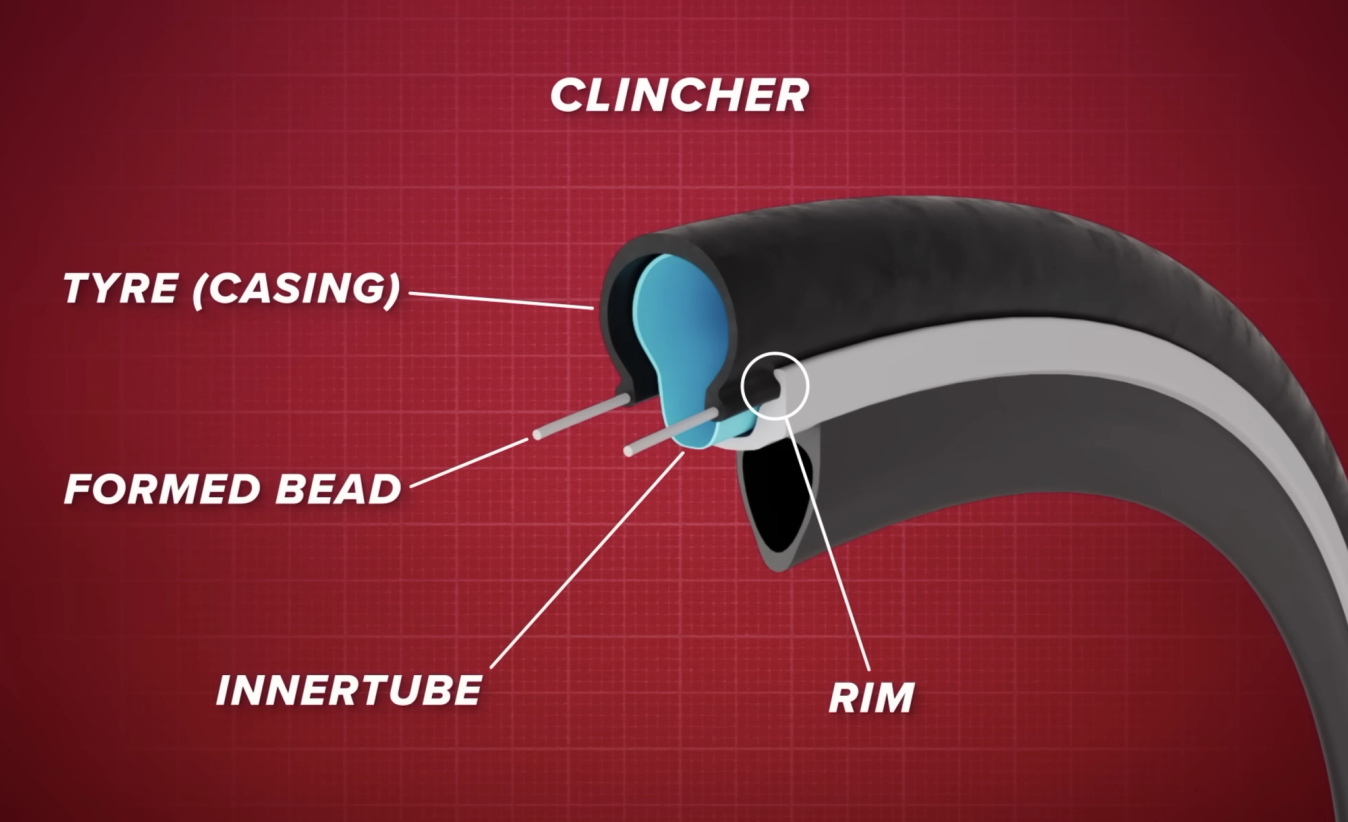

A clincher tyre needs an inner tube to work

The vast majority of bikes have clincher tyres and rims. These tyres have a bead that interlocks with the inner surface of the rim, ‘clinching’ the tyre in place. They use a separate inner tube to hold the air and inflate them.

Clincher tyres are simple to use and cheap to replace, but they have a slightly higher rolling resistance than the other fitment types available.

Read more: How to fix a puncture

Tubeless tyres

© GCN

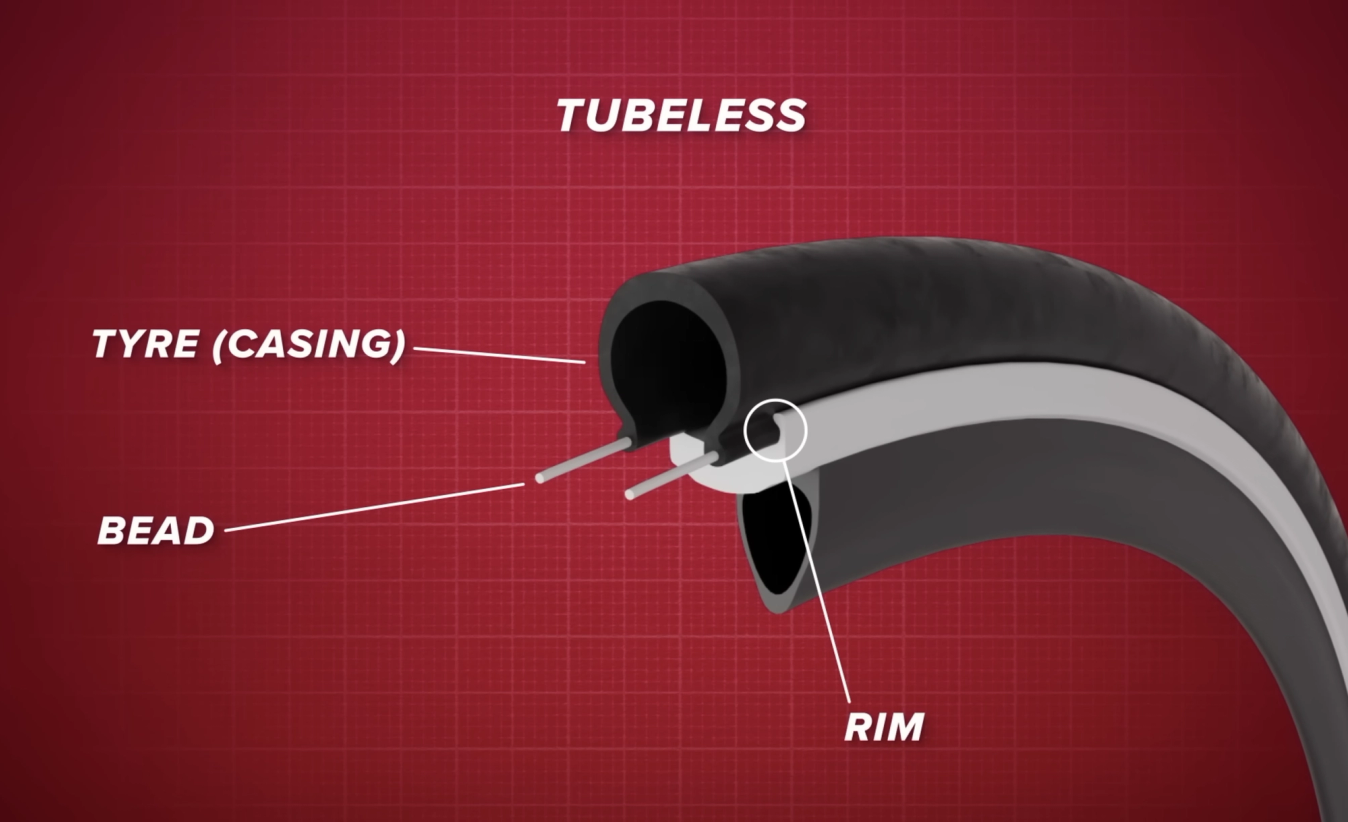

A clincher tyre needs an inner tube to work

Tubeless tyres started out on mountain bikes. They’re relatively new to road and gravel cycling, but they are becoming increasingly common for both amateurs and professionals. The tyres themselves look nearly identical to clincher tyres, but they can be used without an inner tube. For this to work, the rim needs to be airtight, with special tape over the spoke holes, and the tyre needs to have sealant inside to seal any leaks or punctures that happen while riding. The tyres themselves differ from clinchers because they are made to far tighter tolerances, and are air tight without an inner tube. Despite being slightly thicker than clincher tyres, tubeless tyres have very low rolling resistance and superior puncture protection.

In the past couple of years, a new technology has entered the tubeless tyres space: hookless rims present a number of advantages for wheel manufacturers, allowing brands to produce lighter, cheaper and more aero wheels. For hookless to work, though, the tyres have to be made to even more precise specifications than usual. This is a really exciting development, but since it’s so new to road cycling, it’s not relevant to most cyclists. If you’d like to know more about hookless rims and tyres, we’ve got a video that gives you everything you need to know about them.

Read more: How to fit tubeless tyres

Tubular tyres

© GCN

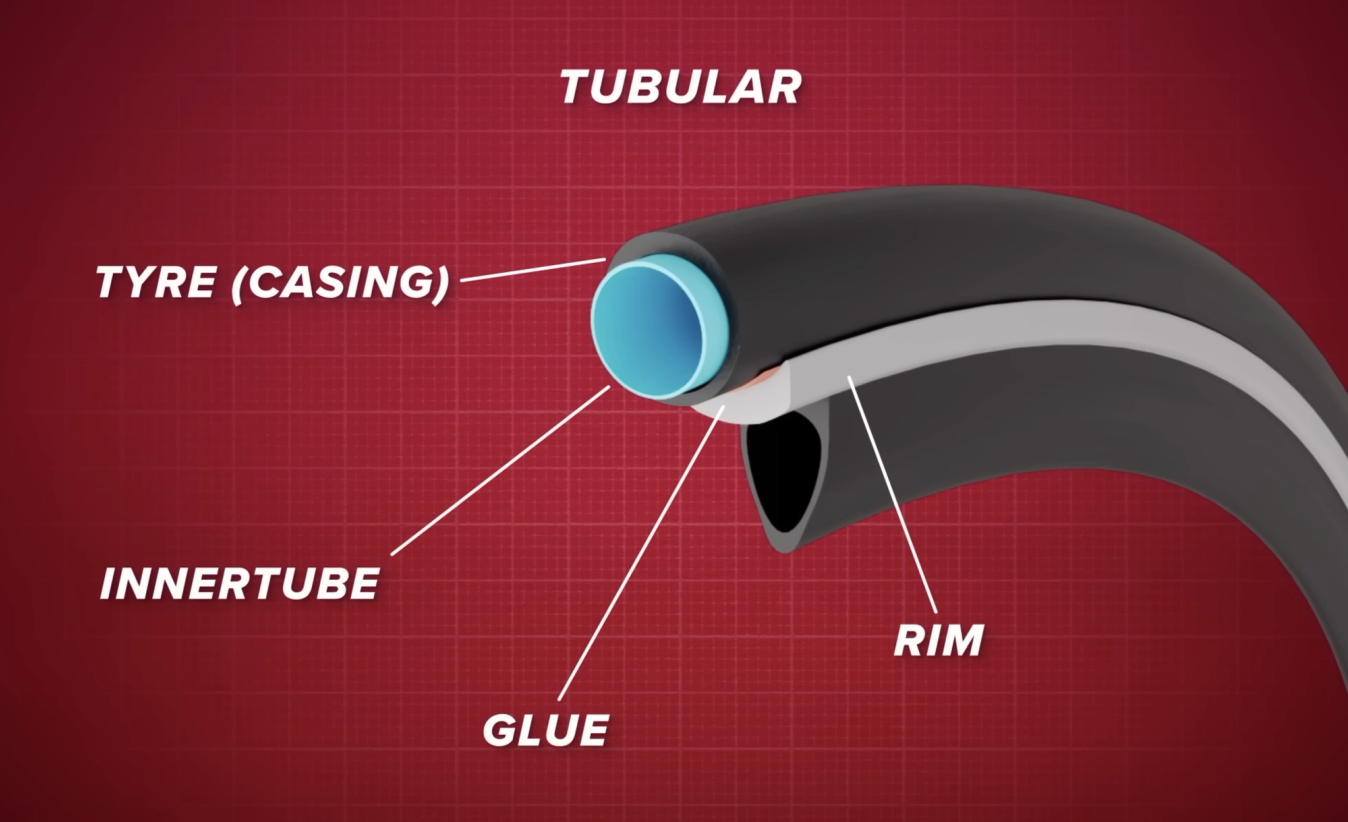

Tubular tyres combine a tyre and tube, and are glued to the rim

Tubular tyres were once ubiquitous in the pro peloton, but in recent years they’ve been usurped by tubeless tyres. Tubular tyres have an inner tube sewn into them, and instead of hooking into the rims, they’re glued on. They offer extremely low rolling resistance, and have a long heritage in road and cyclocross racing. The issue with them is that they have to be glued onto the rim, a very time intensive task. And if they puncture, they’re so difficult to repair that most people just throw them away.

Tyre size

There are a few different sizes of tyre available. Within each of these sizes, the tyre bead – the part that sits on your wheel rim – is the same for every tyre, even if the tyre width and outer diameter changes between makes and models.

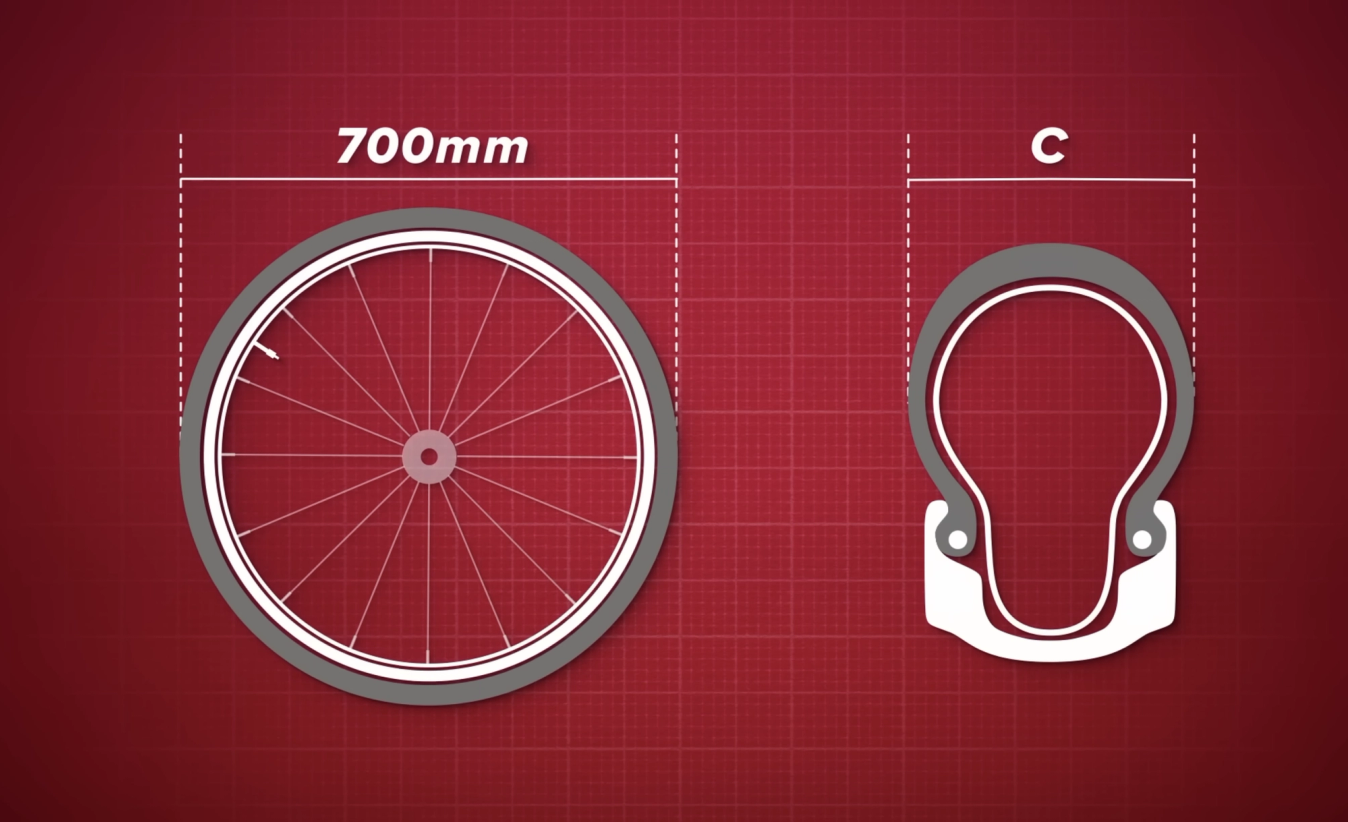

700c

© GCN

700c wheels have a 622mm rim diameter

The vast majority of road and gravel bikes are fitted with 700c tyres and wheels. The internal bead diameter of a 700c tyre will always be 622mm, so, assuming it's the correct fitment type, almost any 700c tyre can work with any 700c wheel.

Mountain bikers have their own version of this wheel size, which also has a 622mm bead diameter, but they refer to it as a 29”.

© GCN

The name 700c comes from the old way of measuring tyre sizes

So why is it called 700c? The name for this size comes from the old French system for tyre sizes, where the outer diameter of the tyre was 700mm, and the width was one of three options: ‘a’, ‘b’ or ‘c’. To maintain that outer diameter of 700mm, loads of different wheel sizes were needed, and the whole system was overcomplicated. To simplify things, bicycle manufacturers decided to keep the wheel size the same, and the modern 622mm diameter was established. The name 700c stuck, though.

650b

Some extra-small road bikes and some gravel bikes use 650b wheels, which have a standard tyre bead diameter of 584mm. 650b wheels and tyres are smaller, so for smaller road bikes, they can give better proportions, as they allow bike designers to scale down their geometries without large, 700c wheels getting in the way.

On gravel bikes, 650b wheels are usually used to allow for wider tyres. A 650b wheel in combination with a wide tyre offers a near identical outer diameter to a 700c wheel with a narrow tyre. For example, there’s only 2mm difference in outer diameter between a 700c wheel with a 32mm tyre and a 650b wheel with a 50mm tyre. By opting for the smaller wheel, riders are able to fit larger tyres in their gravel bike frames, which improves performance on really rough terrain.

This label is another hangover from the old system of tyre measurement: a 650b tyre used to have a 650mm outer diameter and a width of ‘b’.

For mountain bike tyres, this size is referred to as 27.5”.

26”

For commuter bikes, older mountain bikes and some touring bikes, 26” wheels and tyres are common. These have a tyre bead diameter of 559mm, which the eagle eyed among you will notice is not 26 inches. Yes, much like the road standards of 700c and 650b, 26” describes the outer diameter of the tyre, despite the fact that, in reality, the outer diameter of the tyre varies depending on the tyre width.

26” wheel bikes are increasingly rare, but they have a loyal following in some mountain biking circles due to the feeling of agility that comes with a smaller wheel.

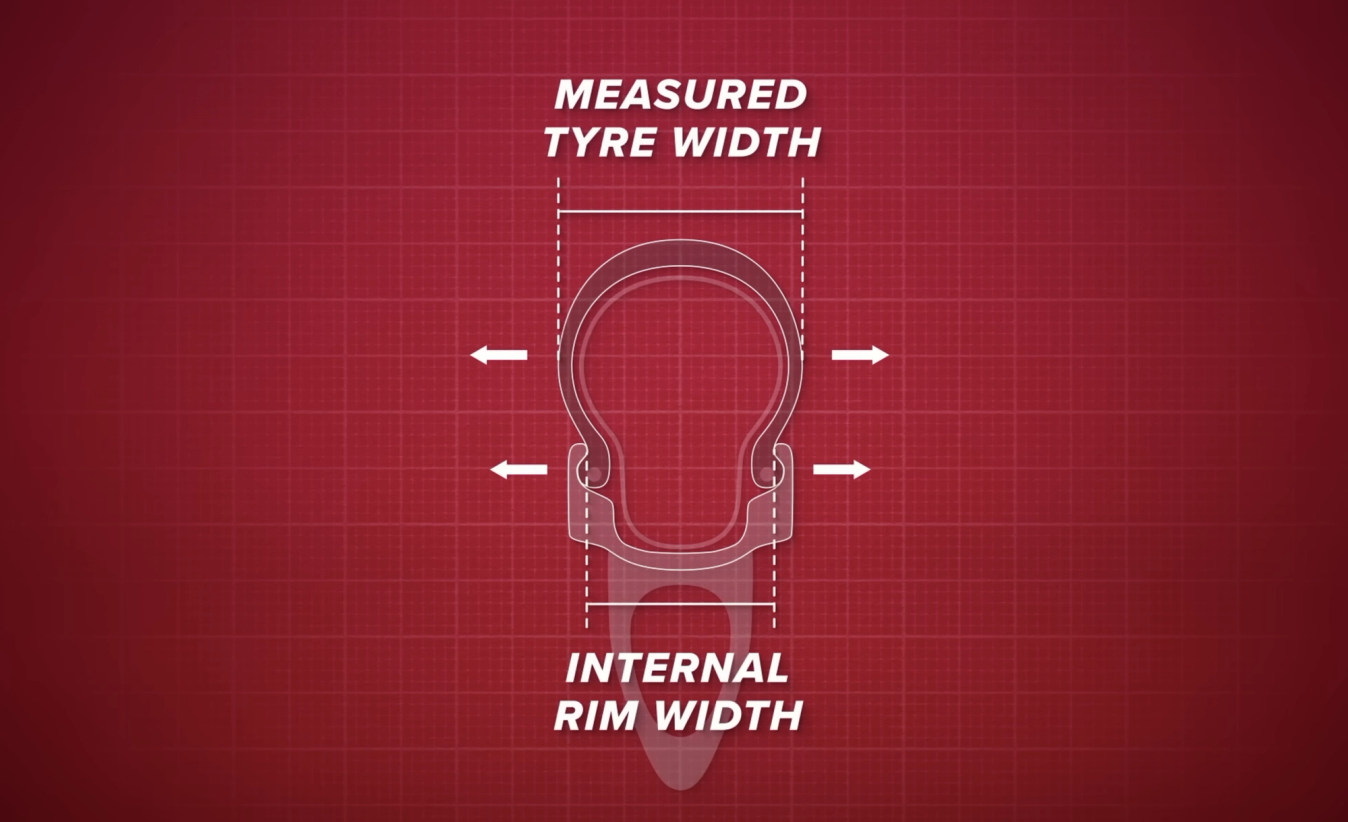

Tyre width

© GCN

Tyre width is affected by the width of the rim

Tyre width describes how wide the tyre is once it's installed onto a wheel and inflated to the correct pressure. On road and gravel bikes, it’s measured in millimetres, but mountain bike tyres give width in inches.

Often, the actual width of a tyre is slightly different from the measurement that’s stated on the side of the tyre, because the width of the tyre is affected by the internal width of the rim. The wider the inner rim, the wider it will make your tyre.

For casual and racing cyclists, 28mm wide road tyres have become commonplace, but anything from 23mm to 32mm is available for normal road bike tyres. For gravel tyres, 33mm up to 50mm is the usual range on offer.

A wider tyre will be more comfortable than a narrower one: it offers a bigger cushion of air to smooth out bumps in the road, and you can run wider tyres at lower pressures, which means they absorb more road buzz. On rougher surfaces, wider tyres roll faster too.

A narrower tyre is more aerodynamic than a wide tyre, so for riders who are racing, or regularly riding north of about 32kph, a tyre of about 25mm to 28mm is the fastest and most efficient, especially on smooth or well-paved roads.

Tyre pressure

Tyre pressure is measured in two units. First of all, PSI, which stands for pounds per square inch. This is what most cyclists use. Alternatively, there’s bar, the metric measurement. One bar is roughly the atmospheric pressure on earth, or 14.5PSI. Floor pumps and some mini pumps will have a gauge displaying one or both units.

On the side of our tyres, we'll almost always see a minimum and maximum pressure. The minimum pressure is the amount of air the tyre needs to be rigid enough to be safe, and the maximum pressure is the highest pressure the tyre can take before there’s a risk of it exploding off the rim.

The pressure you need to use will depend on your tyre width, your system weight (that's you, your bike, and all of your kit), the type of tyre you're using, and the surface that you're riding on. Sounds complicated, but thankfully, most tyre manufacturers provide online calculators for tyre pressure that take all these factors into account.

Calculators aside, the simple principles to go by are:

- the wider the tyre, the lower the pressure

- the heavier the rider, the higher the pressure

- the bumpier the surface, the lower the pressure

- the slippier the surface, the lower the pressure

Ultimately, the best thing to do is to use a tyre pressure calculator from your tyre manufacturer. Whatever you do, make sure that you inflate your tyres to the pressure range given on the side of the tyres.

Tyre casing

The tyre casing is the main body and structure of the tyre. Usually, this is made of a woven cloth material that is covered in rubber. A good tyre casing is strong, flexible, lightweight and puncture resistant, but any tyre has to be a compromise between those attributes. The construction of a tyre casing is measured in TPI, or threads per inch, which describes the amount of threads in a single ply of the cloth-like material that forms the casing.

Perhaps surprisingly, the higher the TPI, the softer and more comfortable a tyre is. Cyclists like to refer to this as ‘suppleness’ – supple tyres give a feeling of floating over the road, as you ride on a cushion of air, not a heavy, rubber casing. High TPI tyres are usually lighter, with less rubber used in the construction.

© GCN

A low TPI means more rubber and better puncture protection

Lower TPI tyres are heavier and more rigid, with more rubber used in their construction. Generally speaking, low TPI tyres offer better puncture resistance than high TPI tyres, and they’re usually cheaper.

In addition to the casing, most tyres have a puncture protection belt in the centre of the tyre, just below the tread. On winter or commuter tyres, this is likely to be very thick, improving puncture resistance but increasing weight and rolling resistance. On summer tyres or race tyres, it’ll be thinner, and the tyre will be lighter, faster, and more likely to puncture.

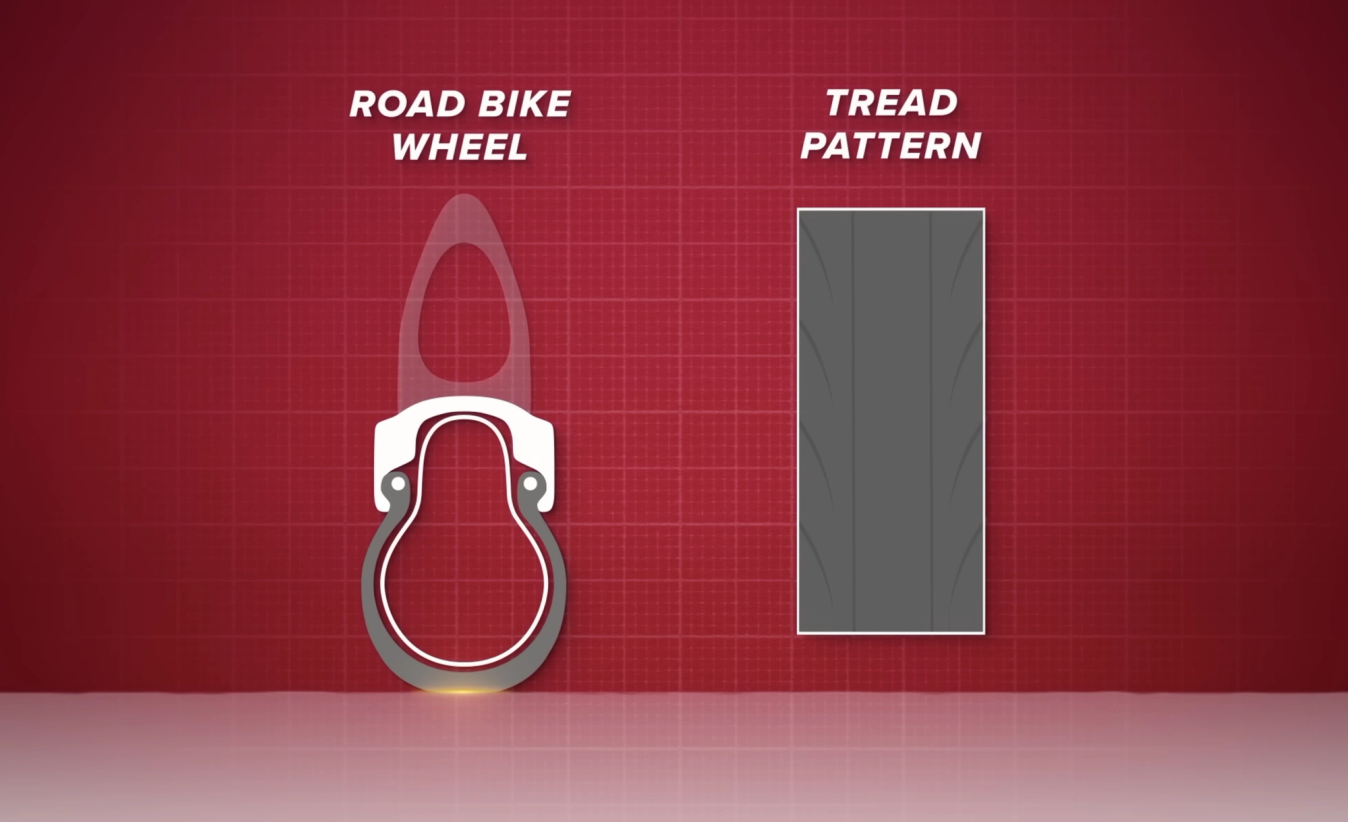

Tread patterns and compounds

© GCN

Road tread patterns are minimal. Traction is determined by the rubber compound

Then there’s the tread, which is the outer layer of the tyre that makes contact with the road. Some tyres have completely slick tread, and others have more pronounced tread, especially if the tyre is designed for off-road or gravel use.

On the road, the tread pattern has almost no impact on the tyre's grip, but on gravel and rough surfaces, a pronounced tread pattern gives extra grip when accelerating, braking or cornering. The downside with having a pronounced tread pattern is that it creates extra rolling resistance.

On the road, the amount of grip a tyre offers is entirely to do with the compound. A softer rubber compound deforms to the shape of the road, giving better traction. Harder compounds don’t offer as much grip, but tyres with harder compounds last longer before they wear out.

Manufacturers produce different tyre compounds for different weather conditions. Winter tyres will have a compound that is soft at lower temperatures, whereas summer tyres will have compounds that are soft at higher temperatures.