Difficulty

Hard

How to install and set up a mechanical groupset

Fitting a new drivetrain isn't easy, but with patience and the right steps, it's straightforward

James Howell-Jones

Junior Writer

These steps will take you through the entire process of fitting a new mechanical drivetrain. We’ve used Shimano 105 for our demonstration, but most of the processes will be the same for other models or manufacturers. If you are unsure of what groupset to get check out our road groupset guide that lays out everything you need to know about all of the main groups out there. If you need to install your brakes too, we’d advise doing these at the same time or just before, especially if you have internally routed cables. See our guide to installing hydraulic brakes here.

Before you start, get all your tools and equipment ready. We've listed all the tools you'll need on the right hand side. Then, set up your frame in a stand. You need the frame in a secure position, without its bottom bracket or wheels attached. Depending on how your cables are routed, you might need to take your forks and headset out too.

Read more: The complete guide to road bike groupsets

How to Steps

Fit the cassette

Fit the rear derailleur

Fit the front derailleur

Measure and cut cable outers

Route the cable outers through the frame

Fit the bars and stem

Install the shifters

Install the bottom bracket

Install the chainset

Position the front derailleur

Calculate the correct chain length

Wrap the chain around the biggest chainring and sprocket

Add a link

Break the chain

Install the chain

Trim the outer cables

Put ferrules or end caps on the cable outers

Route the inner cables

Fix the outer cables in place

Rear derailleur: set the high and low limit

Rear derailleur: set the H (high limit) screw

Rear derailleur: set the L (low limit) screw

Rear derailleur: clamp the gear cable

Rear derailleur: set the B limit screw

Rear derailleur: fine-tune the cable tension

Rear derailleur: cut and seal the cable

Front derailleur: set the L (low limit) screw

Front derailleur: set the H (high limit) screw

Front derailleur: attach the cable

Front derailleur: cut and seal the cable

Front derailleur: adjust the cable tension

Tools Needed

Step 1

Fit the cassette

To start with, fit the cassette to the wheel. Prep the freehub body by smearing a small amount of grease or anti-seize onto the splines. Then, line up those splines with the splines on the freehub – the sprockets will only fit on in one position. Once the sprockets and spacers are in place, put a dab of grease on the lockring before tightening it down using a cassette tool.

Step 2

Fit the rear derailleur

Add a little grease to the thread of the new derailleur, then mount it with the 5mm Allen bolt. It’s very important to make sure that the angle of the derailleur is right. For Shimano derailleurs, the small, swingable piece on top should be horizontal to the ground, with the little nub above the notch on the mech hanger. Make sure you torque the bolt correctly.

Step 3

Fit the front derailleur

Fit the front derailleur to the curved mounting bracket with the 5mm Allen bolt. Attach loosely, and don’t worry about what height to set – you’ll adjust that later. Some new derailleurs come with a ‘support bolt’, which needs to be un-threaded most of the way before fitting the derailleur.

Step 4

Measure and cut cable outers

Now it’s time to roughly measure and cut your outer cables. To correctly measure your outers, hold them against the frame, replicating the route that they’ll take from the front mech to the shifter, and from the rear mech to the shifter. Account for plenty of excess – they need to comfortably run along your handlebars, and they need enough excess to allow you to turn the bars without interference. If in doubt, add more than you need – we’ll trim them to size later.

Step 5

Route the cable outers through the frame

If your bike has internally routed cables, use an internal cable routing kit to find a route through the frame for your gear cables, then use this to guide your gear outers into place. We’ve got more detailed instructions on routing cables here.

Put ferrules on the derailleur ends of the outer cables and place them into the derailleurs.

Top Tip

It’s a good idea to slide a foam sleeve over the outers to prevent rattling inside the frame.

Step 6

Fit the bars and stem

If you haven’t already, fit the bars and stem to the bike. Slide the stem and any spacers over the steerer tube, install and tighten the top cap, then tighten the stem bolts. Don’t worry about setting your headset up perfectly, you can adjust it later once your gears are sorted and your bike is off the stand.

Step 7

Install the shifters

Now install the shifters. Peel back the rubber shifter hood so you can access the clamping bolt, and loosen this just enough that you can slide the shifters onto the drops of the bar. Work them round until the tops of the shifters are level with the tops of the handlebars, then tighten. Don’t worry too much about getting the position exactly right, just gently secure them in about the right spot so we can set up the gears.

Step 8

Install the bottom bracket

Now the cable outers are routed through the frame, it’s time to fit the bottom bracket, if you haven’t already. The process for doing this will vary depending on what type of bottom bracket your frame uses, so have a look at our bottom bracket installation guide to find instructions for yours.

Step 9

Install the chainset

Having correctly installed your bottom bracket, we can move on to installing the cranks. Again, if you're unsure how to do this, we've got plenty of videos detailing the different types of cranks and how to fit them.

Step 10

Position the front derailleur

Now the cranks are in, we can properly position the front derailleur. Adjust the height of the front derailleur until the outer part of the cage sits 2-3mm above the large chainring, and adjust the support bolt until the derailleur is parallel with the chainrings.

Step 11A

Calculate the correct chain length

Put the wheels on the bike, then calculate the chain length.

Step 11B

Wrap the chain around the biggest chainring and sprocket

To do this, wrap the chain around the biggest chainring on the front, and the biggest cog at the back. You don’t need to feed it through the rear mech. Pull the chain tight and match up the two ends, leaving some excess hanging from one end.

Step 11C

Add a link

Find the two links that are the closest to matching, then slide your hand along the excess to add one complete link (one inner and one outer). This is the length your chain should be.

If you’re using a master link you need to leave an inner link on each end of the chain, as the master link acts as an outer link. So, deduct one outer link from the calculated chain length – your master link will make up for it.

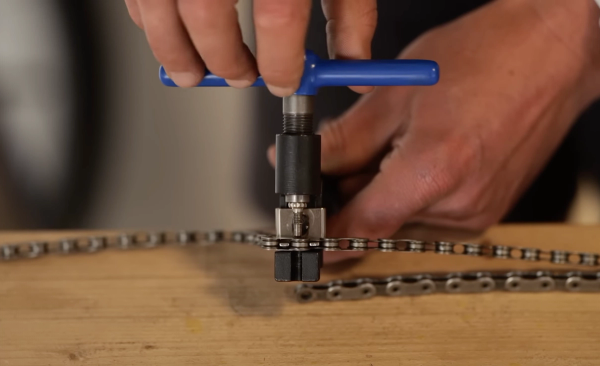

Step 11D

Break the chain

Use a chain breaker tool to remove the excess links from the chain.

Step 12

Install the chain

Thread the chain around the inner chainring, the smallest sprocket and through the derailleurs. Make sure to thread correctly through the rear derailleur so it doesn’t rub on the tab between the two jockey wheels.

Pull the two loose chain ends together and hold them in place with an installation tool or an old spoke. Quick links make fitting the chain easy as you just fit a plate to each end of the chain, join them together and pull on both sides to lock them in place.

Step 13

Trim the outer cables

Before you fit the inner cables, trim down the outer cables to exactly the right length. To do this, and with the gear ends of the outer cable resting in the rear mech and the stopper before the front mech, guide the excess around the bars, leaving enough slack to allow the bars to turn fully in each direction.

You should be able to see how much needs cutting off for the outers to nestle into the shifters.

Step 14

Put ferrules or end caps on the cable outers

Once trimmed to size, put the correct end on the outer cable. There is a specific end for the shifters, that has a ridge on the side and a long, thin end. Don’t thread the outer into the shifter quite yet.

Step 15

Route the inner cables

Now the outers are in place, you can install the inner cables. At the shifters, thread the cable into the cable holder, pulling it all the way through until the barrel is seated correctly inside the shifter. You can then thread the other end of the cable through the outers to the derailleurs.

Step 16

Fix the outer cables in place

Once the inner cables have been pushed all the way through the outer, position the outers inside the shifters, then tape them tidily to the underside of the handlebars.

Step 17A

Rear derailleur: set the high and low limit

All that’s left to do is index the gears, starting by setting the limit screws. These screws determine how far inboard and outboard the derailleur can move and stop the chain going over the largest sprocket into your spokes, or off the smallest sprocket and into your frame. With the chain on the smallest sprocket of the cassette, turn the H screw until the top jockey wheel lines up with the smallest sprocket on the cassette.

Step 17B

Rear derailleur: set the H (high limit) screw

Start with the H (high limit) screw. Loosen it and the derailleur will move outboard, making sure you get all the gears. Tightening moves the derailleur inboard, to make sure your chain doesn’t fall off the end of the cassette. Adjust it until the upper pulley wheel and the smallest sprocket are in line with one another.

Step 17C

Rear derailleur: set the L (low limit) screw

The L (low limit) screw stops your chain going over the lowest gear and into the spokes. Push the derailleur into the biggest gear position while turning the cranks. If the chain won’t go that far, loosen the L screw. If it wants to carry on past the largest gear into the wheel, tighten the L screw. When this is set correctly, the upper pulley wheel should line up with the largest sprocket.

Step 18

Rear derailleur: clamp the gear cable

Click the right shifter down the gears until it stops clicking, check the outer cable is properly snug in the guides, the shifter and the derailleur, and check that any barrel adjusters on the cables are wound fully in. Thread the inner gear cable around any guides on the derailleur, pull it tight and clamp into place.

Step 19

Rear derailleur: set the B limit screw

The shifting might not be perfect yet but it should be close enough for you to shift into the largest sprocket so you can set the B-limit screw. This is located at the back of the mech here and adjusted with a 2-millimetre Allen key. The B-limit adjusts the gap here between the top pulley wheel and the largest sprocket. Adjust until you have a 5mm gap between the largest sprocket and the teeth on the upper pulley wheel.

Step 20

Rear derailleur: fine-tune the cable tension

Next, fine-tune the cable tension to make the gears shift correctly. To adjust the cable tension, turn the barrel adjuster. If the gears are struggling to shift into a larger sprocket, you need more tension, so turn the barrel adjuster anti-clockwise. If the gears are over-shifting, or are struggling to move to a smaller sprocket, you need less tension, so turn the barrel adjuster clockwise.

Step 21

Rear derailleur: cut and seal the cable

The last step for the rear mech is to cut off the excess cable, leaving 30-40mm of excess, then protect the raw end with an end cap. Slide a cable end on and crimp it in place.

Step 22A

Front derailleur: set the L (low limit) screw

Put the chain on the small chainring and the largest sprocket of the cassette. Turn the L limit screw while pedalling the bike in the stand until you can hear the chain rubbing on the inside of the derailleur, then, then turn the screw a quarter turn anticlockwise. The derailleur should just about miss the chain.

Step 22B

Front derailleur: set the H (high limit) screw

Next, set the H (high limit) screw. Before you can set it, you need to change into the smallest cog at the back and the big chainring on the front. Then, while pushing the front derailleur out to its limit with your hand, turn the H limit screw until there is 1mm or so of space between the chain and the outer plate of the derailleur.

Step 23

Front derailleur: attach the cable

Next, attach the cable through the pinch bolt on the front derailleur. To access the bolt, remove the small plastic cover, and set it aside. Click into the smallest gear at the shifter, thread the cable through any frame guides, and clamp it under the pinch bolt while pulling the end tight.

Step 24

Front derailleur: cut and seal the cable

Leave about 30 to 40 millimetres of excess cable, then cut it to length. Before putting on the cable end, slide the plastic cover over the cable – this cover guides the cable and tucks it away neatly. Finally, crimp on a cable end cap, and tidy away the excess with the plastic cover.

Step 25

Front derailleur: adjust the cable tension

The final step is setting the cable tension for the front derailleur. Put the chain in the middle of the cassette and try using your shifter to move the chain to the large chainring. If it fails to shift, there’s too little cable tension. Increase the tension with the 2mm micro adjustment bolt near the cable clamp.

GCN's Essential Road Bike Maintenance

For road, gravel, commuter and hybrid bikes, Essential Road Bike Maintenance is intended to be a proper bible to all those essential bike maintenance, repairs, and set-up tasks that we all need to know. Everything from basic bike set-up, how to get your wheels on and off, through setting up gears, bleeding brakes, and beyond to things like installing electronic gears, converting to a 1x transmission and more. In a nutshell, pretty much everything you would want to tackle on your bike (or bikes, plural) yourself. And then some. Like bike set up tips for taller and shorter riders; bottom bracket standards explained; common bike maintenance mistakes and how to avoid them; essential roadside fixes to keep you riding; how to make your bike more comfortable; how to puncture-proof your ride and much, much more. “A huge amount of knowledge, hacks, and know-how to help improve both your workshop skills and your ride” – Ollie Bridgewood, GCN Presenter Each chapter is structured with the tasks you’ll most likely need more of the time at the start (like how to adjust your gears, replacing brake pads, or changing a tyre), before running through to those that you’ll do much more infrequently (such as changing disc brake hoses, servicing a freehub or pedals, and so on). This also means that many of the tasks naturally ratchet up in difficulty as you go through each chapter which should also mirror your natural progression as you become more mechanically capable and confident. In short, 260 pages packed with all the essential knowledge you’ll need to confidently take on and complete pretty much any bike maintenance task. Get Some ‘Show-How’ With Your ‘Know-How’ Each walkthrough is linked to a companion video which you can watch for free from your computer, tablet or smartphone. To watch, either type in the walkthrough’s short-link URL – e.g. https://gcn.eu/GetPerfectShifting – into your browser, or scan the QR code with your smartphone or tablet so you can get the best of both worlds: know-how and show-how. Simple. All you need to know to fix your bike. Product Details: Pages: 260 (120sm) Size: 280mm (h) x 216mm (w) (portrait) Cover: Paperback Cover Finish: 300gsm, silk stock with anti-scuff matte laminate and spot UV gloss finish Please note: There may be some additional shipping charges for orders consisting of 2 or more books. However, our customer service team will contact you after you have placed the order to advise on delivery options. Click here to explore all GCN best selling books