Industry Myths Busted by Silca CEO Josh Poertner

Poertner joins Alex Paton and Ollie Bridgewood to explain some of the ways the industry operates and markets its products

Alex Hunt

Junior Tech Writer

The cycling industry has never been so full of choice for us the consumers, but with all this choice comes an overwhelming volume of marketing hype and claims. With bike prices higher than ever are we all falling foul to clever branding and industry trends, or are the claims being made legitimate? Luckily for us, we have somewhat of an insider to hand on this topic.

Josh Poertner is the current CEO of Silca and has over 24 years of experience in the bike industry working with Zipp and SRAM as well as being integral in the development of the CSC WorldTour team.

Is there any truth in the aero data that is released by brands?

We have all seen product launches for new bikes or wheels that claim that it is a class leader in aerodynamic efficiency. The issue is that there is no industry standard aerodynamic testing protocol that makes all data completely comparable. Poertner does believe that most of the big brands are honestly representing the data that they have recorded.

© GCN

Aero testing from brand to brand isn't standardised meaning results can show different things based on the individual testing protocol

Without a testing standard, it is hard to make genuine comparisons between each brand's claims. There are also some ways in which data can be manipulated in order to provide the intended results. Testing wheels in isolation rather than fitted to a bike is one example but also how slowly equipment is rotated in a wind tunnel can vary the yaw angle that a product can achieve before air flow stalls leaving the surface.

As much as this is not necessarily a case of brands being dishonest it does highlight that testing data from the manufacturer itself does need to be taken with a pinch of salt. For the most meaningful aero data an independent test that puts each product through an identical testing protocol is required.

Are all top-tier bikes actually as good as each other?

With every brand looking to improve their bikes in the same direction - making them more comfortable, more aerodynamic and following industry trends for wider tyres - is it safe to assume that the best bikes from each brand are close enough in performance to be deemed as equal? Although there has been a lot of convergence in bike design, especially in the performance road sector that is largely dedicated to the restraints UCI equipment rules put on manufacturers, there are still variances between brands that require consideration.

What is interesting is that the changes in the UCI rules for this year allow deeper aero profiles in bike design, so we are likely to see the differences in bike design grow again for the next few years, much like we see in Formula 1 with regulation changes.

How much difference does the bike make?

Ollie took the opportunity to ask Portner a hypothetical question as to whether Jonas Vingegaard (Visma-Lease a Bike) would still be able to win the Tour de France on any of the WorldTour bikes or if the differences in equipment make up more than his winning margin.

Josh is quick to point out that in this era of cycling the range between the best and worst-performing equipment has massively narrowed with most setups within a few per cent of each other. There is still a bigger discrepancy between teams when it comes to time trial tech with the performance gains of the best equipment still sizeable when compared to the worst-performing setups.

Poertner seems to attribute this difference to a different rate of aerodynamic education across different brands. The ones that have been slower to adopt the new aero practices are now playing catch up to get on terms with the more science-led brands. Something that he does think has massively changed the landscape is the move from most teams to include a technical director as part of their staff. A large majority of them come with an engineering background and provide an objective perspective on equipment selection and configuration.

Do white papers that fail to name the competitors they were tested against lose some of their credibility?

It is all too common that a new product is released with a supporting white paper that claims to prove the superiority of the product without actually listing the competition it was tested against. We see all the time that the white papers simply label the tested rivals as brands x, y and z. This arguably lowers the weight of these claims as consumers have no idea what exactly the product is better than.

One reason this happens is to try and limit any damage or shade-throwing on a competitor's product. A white paper is typically used to prove a concept rather than as a marketing ploy so it is more considerate to keep the tested equipment anonymous and simply state the performance gains the new product has over the competition.

Stiffer, lighter, more aero?

We have asked Poertner about stiffness in the past with him hinting that one of the magazines that tested the bike's stiffness led to a race to create the stiffest bikes. The issue with this is stiffer isn’t always better. Stiffness needs to be optimised rather than maximised and the performance of a frame stiffness should be spoken in regards to each axis more openly. A frame with no vertical compliance could be very stiff however it is also going to ride terribly and feel very harsh.

As far as weight is concerned some brands are looking for new ways to win the weight weenie battle by shipping bikes as standard with lighter TPU tubes. The reason behind this is once again to win reviews in magazines where bikes are frequently weighed straight out of the box. Although there is nothing inherently wrong with this it does mean that for these bikes riders are left with fewer avenues to reduce the bike weight than they might expect.

Do you think brands should be more transparent about where bikes are manufactured vs where they are designed?

Numerous cycling brands are quick to tell you that their products are designed in the USA or Europe however this is only half of the story. Although the product may be been designed by a team of engineers in these western regions almost all cycling products are still manufactured in East Asia.

The reason behind this is simply to reduce labour costs. A lot of cycling components especially carbon fibre manufacture are very labour-intensive with very little of it automated. The move to Asian manufacturing in the 90s was seen as a way to undercut the competition and get products to market for a lower overall cost.

Poertner does think that over the next few years, we might see a trend known as onshoring where brands look to bring their manufacturing back to their home nations. After the COVID-19 pandemic, the fragility of supply chains has never been more obvious and moving operations back to a more controllable location is no bad thing.

What is the one area that isn’t worth the marketing hype?

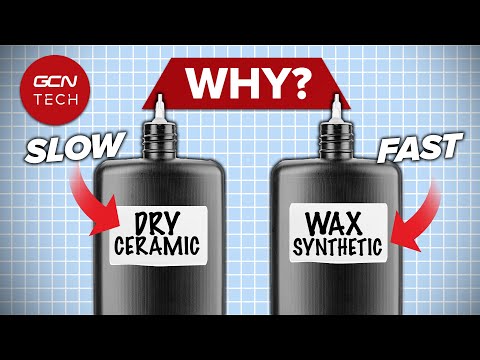

We have looked at some of the worst bike upgrades you can do in the past and Poertner sides with one of our inclusions on that list. Ceramic bearings as far as cost-to-benefit is concerned are one of the least effective upgrades you can make to your bike. He adds that the benefit at 30mph is under a single watt by swapping over to ceramic bearings.

Something that is not so often discussed is the increase in care that ceramic bearings require. Without the rubber seals, ceramic bearings are subject to contamination and dirt ingress way more than a typical steel bearing. If they aren’t frequently serviced the tiny benefits that they can offer quickly diminish to zero.

Ollie is also a believer that most weight-saving claims are not worth the massive hype that surrounds them. For sure, lighter will be faster on a climb but it is commonly misunderstood how small of a difference a seemingly significant weight saving will have. A 1kg difference in weight on a one-hour climb is worth around 30-40 seconds. Obviously, if you are at the pointy end of a Grand Tour that is a benefit you can’t throw away but for everyone else, it is hardly worth worrying about.

Does the industry have anything it doesn’t want you to know?

In a ground-breaking development, Poertner reveals that some brands will create one frame type and at the end of the production line will weigh each frame with the ones that reach a weight threshold being used on cheaper models and the lighter frames become the more premium bikes.

He does say that this is simply selective assembly around the lighter frames. This variability comes from the manufacturing process of carbon fibre. As the frame is moulded the resin gets pressed through the fibres and some of it is purged out. Frames that purge more resin will naturally be lighter and can become more premium models.

In a similar vein, Poertner shares his experience regarding clear-coat carbon bikes. He says that these are the best frames the manufacturer makes as it is incredibly difficult to cover up any defects or imperfections in the carbon. He adds that clear-coated frames are often reserved for the brand's most premium bikes and command an equally premium price.

Have these industry myths changed your perception of the industry, share your thoughts with us down below and make sure to check out the latest GCN Tech Show where Alex and Ollie are discussing the seemingly ever-rising cost of bikes.